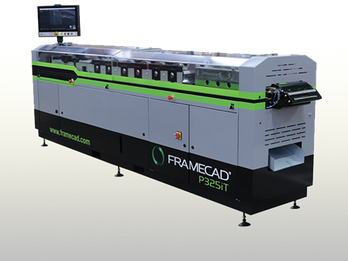

Manufacturing Equipment

FRAMECAD's cutting-edge cold roll forming machine sets the benchmark for precision and efficiency, with a strong emphasis on continuous innovation.

What is cold roll forming machine?

A cold roll forming machine, commonly referred to as a rollformer, is utilized for shaping robust steel elements at ambient temperature. Its primary purpose involves processing extensive metal lengths to manufacture an array of metal goods. The configuration of a cold formed steel machine's cross-sectional profile is typically customized to meet the specific requirements of customers. Additionally, the machine's rollers can be modified to produce various shapes and sizes. This meticulous process enables the rapid and accurate production of substantial quantities of components.

Enhance precision and productivity in production.

Elevate operational efficiencies and achieve unparalleled precision in cold formed steel manufacturing through the utilization of FRAMECAD's state-of-the-art cold roll forming machine. Engineered and crafted in New Zealand, this advanced roll former seamlessly integrates cutting-edge technology, engineering expertise, design capabilities, and production software to generate readily assembled frames, trusses, and joists with utmost ease.

Utilizing the most efficient design and manufacturing technology for cold formed steel globally, FRAMECAD equipment incorporates a specialized servo-drive motor in conjunction with a top-tier encoder system. This exceptional combination ensures the production of punches, cuts, and chamfers with an extraordinary tolerance of less than 0.01mm.